CONTACT US

Would you like to speak to one of our scientist? Just submit your contact details and we’ll be in touch shortly. You can also email us if you prefer that type of communication.

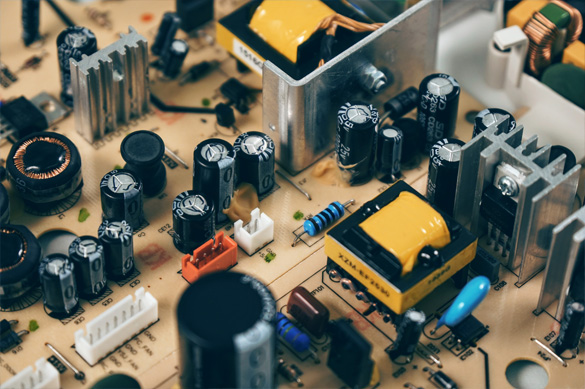

The Global Electronics industry is worth a staggering $1.8 Trillion every year in value. It is one of the most sought out after sector for technology innovations as well because the success for key players in this sector depends on how effectively they are able to offer great devices at fabulous prices at profitable margins to win customer hearts.

Price optimization is one area that depends on how well you can source components and how effectively you can manage logistics to come up with favorable market supply. Being undoubtedly one of the largest industries in the world electronics manufacturers are facing newer challenges in ensuring quality of the devices they produce in mass scales. Over the past decade, people are increasingly relying on electronic devices that do more than what they did previously or in other words people are buying smarter electronic devices. From the smallest handheld MP3 players to large smart refrigerators, the avenue of smart consumer devices has grown tremendously. Nearly all of them have touch screen enabled interfaces and also has embedded software installed in them to operate as a smart device according to user interactions.

In fact Internet of Things (IoT) enabled smart homes will be one of the most invested sector in the coming years and smart homes will definitely include smart appliances such as smart televisions, refrigerators, etc. To offer great and reliable electronic devices, however it is imperative to offer great levels of product stability, intuitiveness and most importantly a fault free product. Over 24% of all accidental home fires are reported to have occurred due to faulty electronic appliances.

This is where product testing is viewed as a major requirement. Every year companies spent billions of dollars on testing product quality and reports suggest that nearly 35% of the overall QA budgets in the electronics industry is reserved for testing user interfaces i.e. touch screen displays embedded on appliances.

Employing a significant workforce to achieve this testing feat will push up operational expenses by a huge margin and thus companies are always looking for newer avenues to test electronic device interfaces with minimal cost.

In India alone the market for electronics and home appliances would reach a taggering $400 billion by 2020 according

to expert studies.

The SR-SCARA-Pro robot is the game changer for this scenario as it ensures that electronic devices are well tested before deployment towards actual usage without human intervention.Each device needs to pass through various rounds of Quality Assurance measures to ensure that end users do not face any hassles while using them on a regular basis. And this QA process starts not after a final product comes out of the production line but right from the time successful prototypes are designed from great ideas.With the SR-SCARA-Pro robot, there is a huge opportunity for companies to prevent faulty devices from being shipped to stores from their production lines.

The robot is intelligently designed to collaborate with both external hardware components such as touch screens, buttons, knobs and other control devices as well as with software control modules will ensure that the end product is trustworthy and market ready.The SR-SCARA-Pro robot can integrate with renowned software quality assurance frameworks and control systems to automate the testing of all software components and check against desired functionality outputs. On the hardware side, the robot ensures that sensitivity, touch screen intuitiveness and usability are thoroughly tested during the entire production lifecycle.With SR-SCARA-Pro, manufacturers have several advantages when compared to legacy manual QA measures.